These, are detected at varying concentrations in the effluent streams and mixed liquors of the reactor systems. During these processes, the hydrolysis of target solid wastes followed by the microbial conversion of them to biodegradable organic, content results in the production of intermediate VFA, commonly acetate and butyrate. These include fermentation, anaerobic digestion and recovery from discharged chemical and industrial plants effluents. With the constantly rising awareness of the environmental impact the carbon based economy has created, research has been focused in developing alternative methods of their production. Regardless the scarcity faced in coal based fuels, VFA are still extensively and in most cases solely, synthesised from petroleum. In the current era, technological and economic development is widely based on the limited global petroleum resources. In addition to supplying the equilibrium data, these tests can reveal phase behavior near the liquid-liquid interface such as emulsification or entrainment that help guide extractor selection.The recovery of volatile fatty acids (VFA), from complex effluent streams deriving from numerous sources has been an area of research interest for more than a century. When conducting an extraction pilot test, it is highly preferable to use actual plant feed and solvent materials.īefore pilot testing begins bench scale tests are performed to generate liquid-liquid equilibrium data. Dispersed phase entrainment, emulsification tendency and the impact of impurities at the liquid-liquid interface are some of the common phenomena that occur in an extraction column which makes pilot testing essential.

#Liquid liquid extraction in downstream processing software#

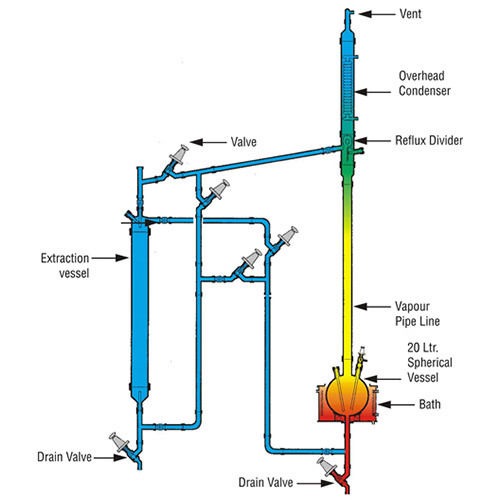

Unlike distillation processes, which can often be designed using process simulation and hydraulic rating software alone, extraction involves complex chemical phenomena at the liquid-liquid interface which is very difficult to model to allow for commercial scale process design. Nearly all extraction projects require pilot testing to provide the basis for commercial process design and a process performance guarantee. However, liquid-liquid extraction has become the standard for certain processes, such as the recovery of high boiling organics or non-volatile inorganics from dilute aqueous streams.

Distillation is often considered first in the hierarchy of separations methods, and is taught extensively in chemical engineering curricula. Our liquid-liquid extraction / solvent extraction design expertise includes sieve tray columns, packed (SMVP) columns, pulsed columns, rotating disc contactor (RDC) columns, SCHEIBEL® columns, and KARR® columns.Īt Koch Modular, we do more than sell extraction equipment we supply solutions to difficult separation challenges. Our LLE / SX columns are engineered to fulfill the challenging purification requirements that exist in the alternative energy, biobased & renewable chemicals, flavor and fragrance, metals and mining, petrochemical and hydrocarbons, pharmaceuticals, polymers, and specialty chemicals industries. The Koch Modular Extraction Technology Group has decades of experience designing and supplying liquid-liquid extraction (LLE) / solvent extraction (SX) equipment.

0 kommentar(er)

0 kommentar(er)